Safety, energy conservation, and a people-oriented approach

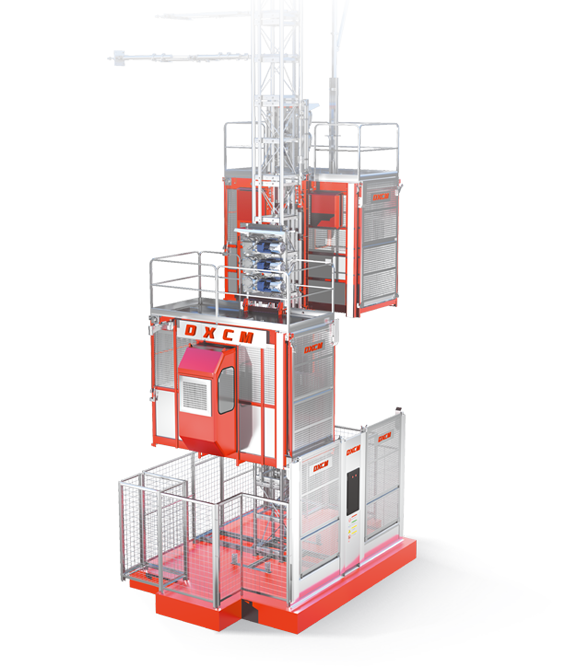

DXCM SC200/200 Construction Hoist

At DXCM, we are not just manufacturers; we are guardians of quality. Our quality control team meticulously monitors every stage of production to ensure that each elevator meets our high standards. Technological innovation is the key to our success. We actively incorporate cutting-edge smart technologies to continuously enhance the performance and safety levels of our products.

The transmission system adopts a new type of worm gear and helical gear high-speed reducer, replacing the traditional worm gear reducer. This not only significantly increases efficiency but also eliminates damage faults caused by easily worn worm gears, extending the service life of the entire machine. Each lifting cage requires 13KWX2 motors, making the entire machine a 4-motor 52KW system, saving 14KW compared to traditional 6-motor rack machines. The cage structure which focus on quality and practicality, Ensuring effective usage period, the cage remains free from deformation, operates quietly that is equipped with a high-quality lacquer to strengthen anticorrosion. Overall, it reflects a commitment of safety, durability, and practicality.